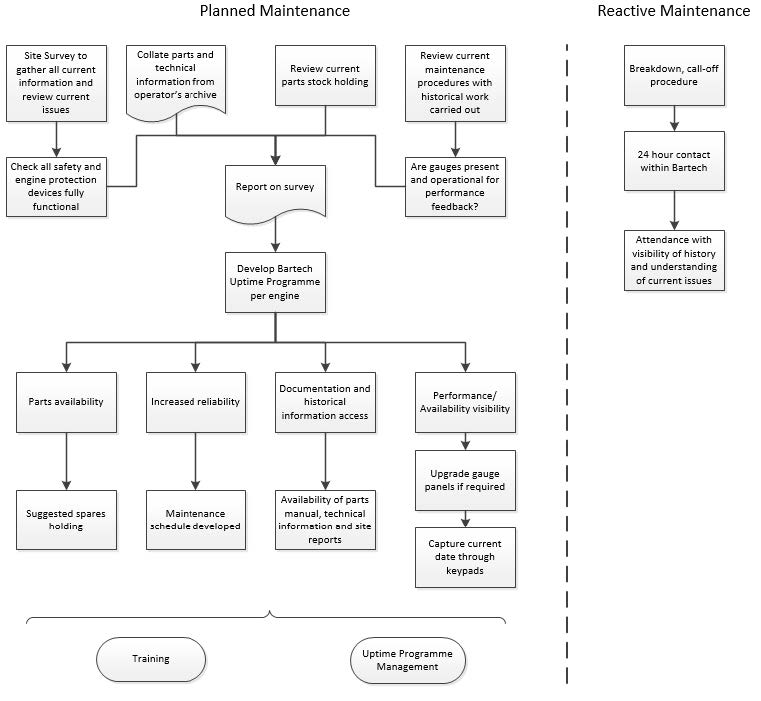

Bartech can help you with your maintenance planning, whether it is optimising any current plan you may have in place, or creating one to suit your situation.

With over 30 years of experience, Bartech will ensure your maintenance plan is correctly optimised and time-efficient for your particular engine use and environment.

We extend our knowledge of each operator’s needs through developing our understanding of their engines. We achieve this with the feedback of testing samples and temperatures before any intrusive work takes place.