Looking for help with Emission Reduction?

At Bartech, we’re always searching for new ways to improve your engine reliability and performance, and in recent years, we’ve become increasingly aware of the importance of environmentally friendly products and systems too.

As a result, we’ve spent the last five years researching the options for emission reduction and assessing the pros and cons of each one.

Many systems rely on storing the hydrogen, limiting viability for many operators, due to the space required and the additional safety measures associated with storing this flammable product, and the by-product created over time – Acid.

The acid is created when electrolysis takes place. Electrolysis of water makes hydrogen and oxygen by passing a current through a catalyst like platinum.

The scientists working on our product have found a way to use distilled water which creates no acid.

The next step was to seek a solution that would avoid the above issues. We were successful in this, but whilst hydrogen storage was not essential, they required an alkali solution to create the reaction to produce hydrogen. This is toxic and would mean that hazmat suits were required during refills. These systems also had a short life span – just 1 year.

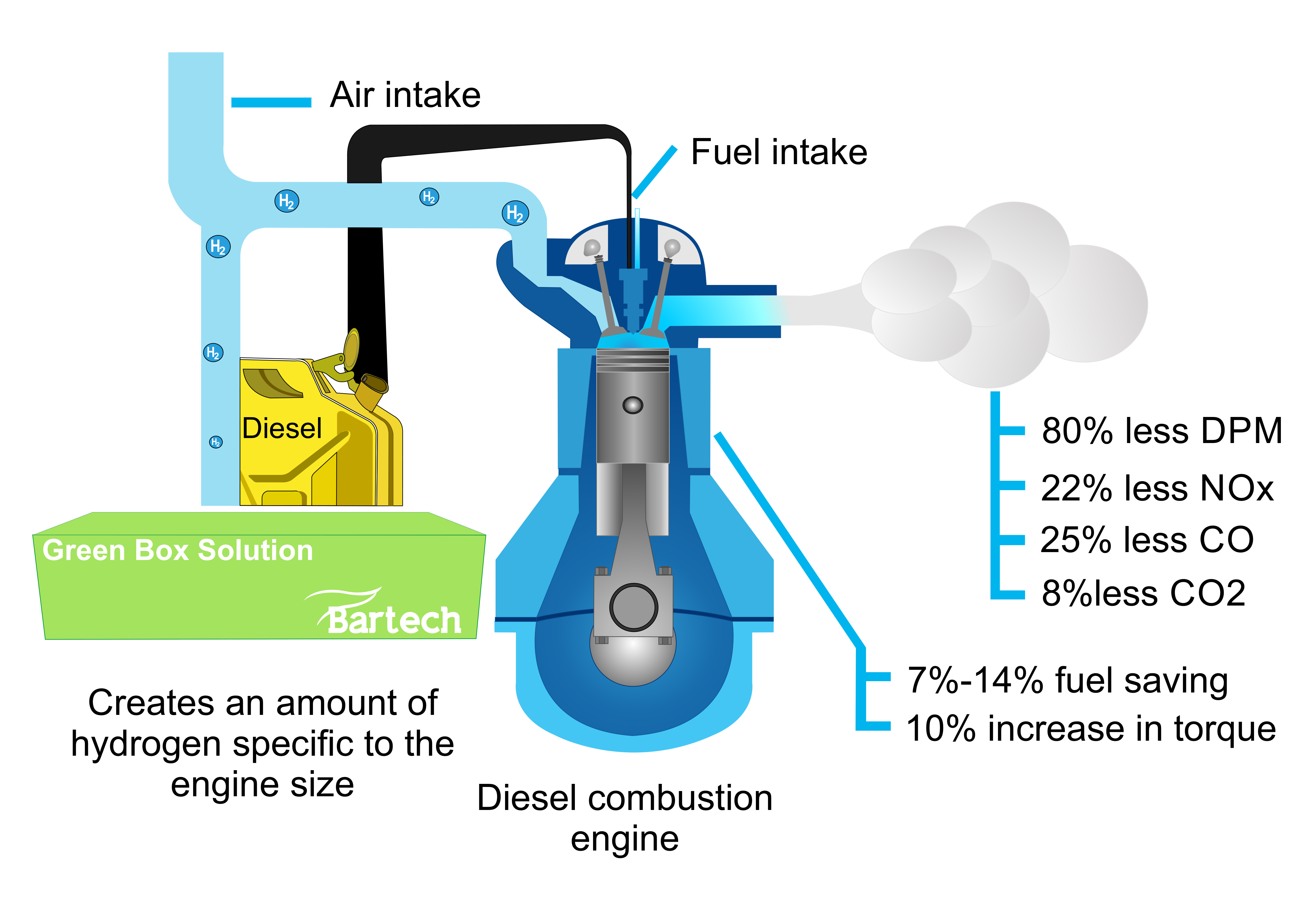

We are now pleased to have the answer, the Green Box Solution

- Direct feed – generates hydrogen on engine demand from the ECU, reducing the diesel fuel required for your operation.

- What is it powered by? Distilled water

- The by-product? Steam

- Life-Span? 25 yrs+ (6-month service after installation followed by annual servicing)