To put it mildly, we’re all experiencing challenges at the moment, and there are three things our clients are struggling with most:

- Rising prices

- Lack of availability of parts

- Long wait times for services

And at Bartech Marine, we believe in innovating to help our clients, and thought we’d share how we helped one operator avoid one month of additional downtime while saving money at the same time…

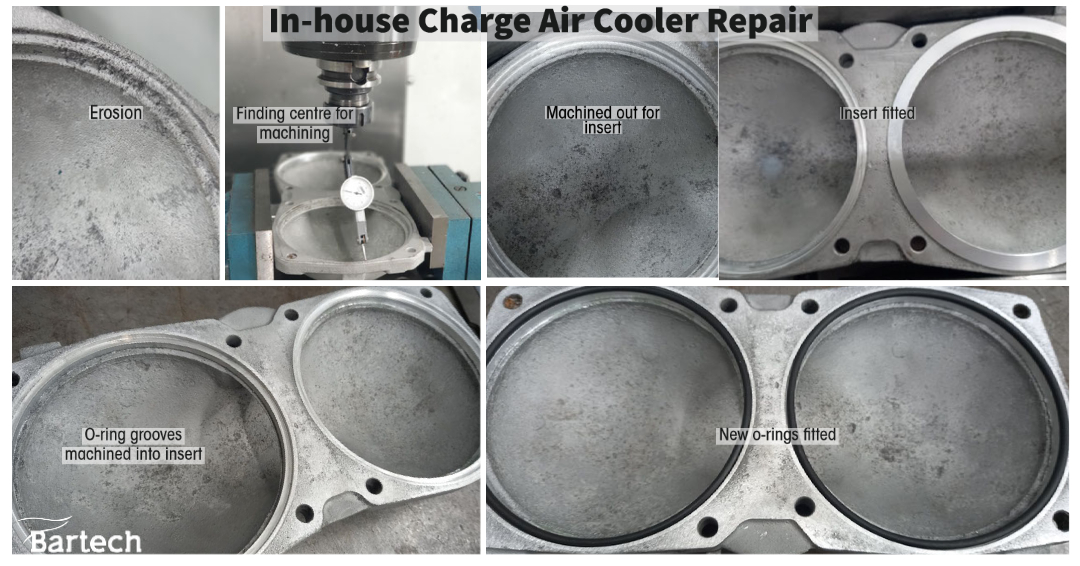

While overhauling their engine, we discovered that the charge air cooler had eroded, causing it to fail and leak.

It could be replaced, but at a cost of over £2,000 and with a month-long lead time – not ideal when you’re relying on the engine.

Fortunately for the customer, we have in-house machining capabilities and a highly skilled senior machinist.

After evaluating that there was enough good material left as a starting point, we got to work repairing the charge air cooler instead.

For this cooler, the erosion was machined out allowing an insert to be fitted to the housing.

With the insert in place, the o-ring groove was machined to ensure a perfect seal between the housing and o-ring on reassembly.

This is just one example of how we think differently and have the equipment and skills to offer you alternative solutions where others may not.

Since starting in 1987, it has been our priority to deliver the equipment and services operators need, when they need them.

And with fully equipped facilities and a team of experienced engineers and machinists, we continue to focus on these key elements, providing more and more solutions to the struggles we are seeing operators face.