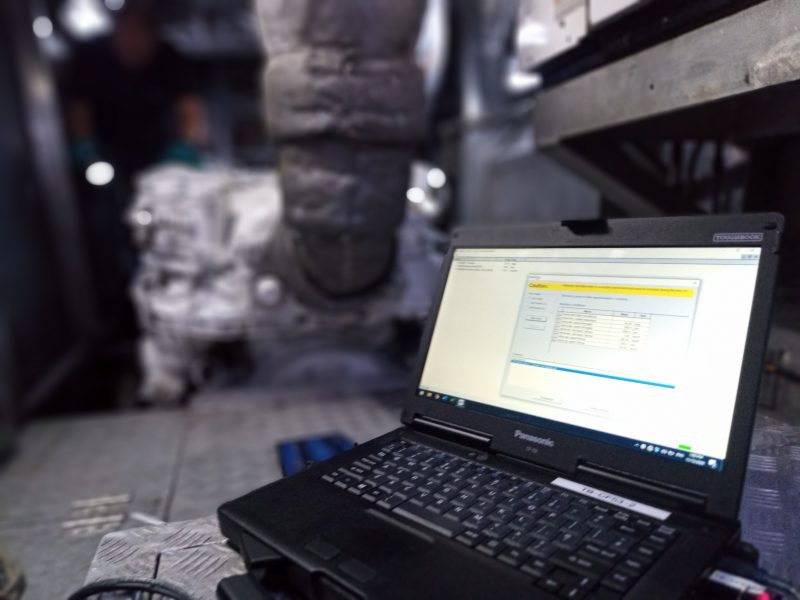

Last week one of our MTU trained engineers, Matt, headed out with his laptop, complete with DiaSys diagnostic software.

He was tasked with looking at a couple of MTU 20V4000G62 generator sets, which were having various problems with alarms, hunting and synchronisation.

Once Matt got onsite, he started to look at the hunting and synchronisation issues on the first set by connecting up the laptop to see what information there was from the MDEC.

This engine was started and with no load, the fuel pressure was shown as 900 bar.

As soon as load was put on the engine, the pressure dropped to 300 bar.

This drop in pressure will have resulted in the issues experienced by the end user, so Matt’s next job was to locate and rectify the cause of the pressure drop.

Starting with basics, Matt asked when the fuel filters were last changed. To his surprise, there was NO record, and nobody knew when they’d been changed.

It’s not the first time we have come across this lack of record keeping, and I doubt it’ll be the last, but it is so fundamental that I thought it was worth reiterating.

Proper maintenance records on all work carried out on your engines – along with historical data – will tell a lot about what is going on, allowing prevention of expensive, costly downtime.

I don’t understand how people can have confidence in their critical engines if they have no idea of how it’s been looked after?