How many turbos have you rebuilt in your time?

Even if your answer is “none”, then the chances are that as an engineer you understand the need to follow the right processes with the right parts.

Because if you don’t, you could well end up in a situation like the vessel owner we are working with.

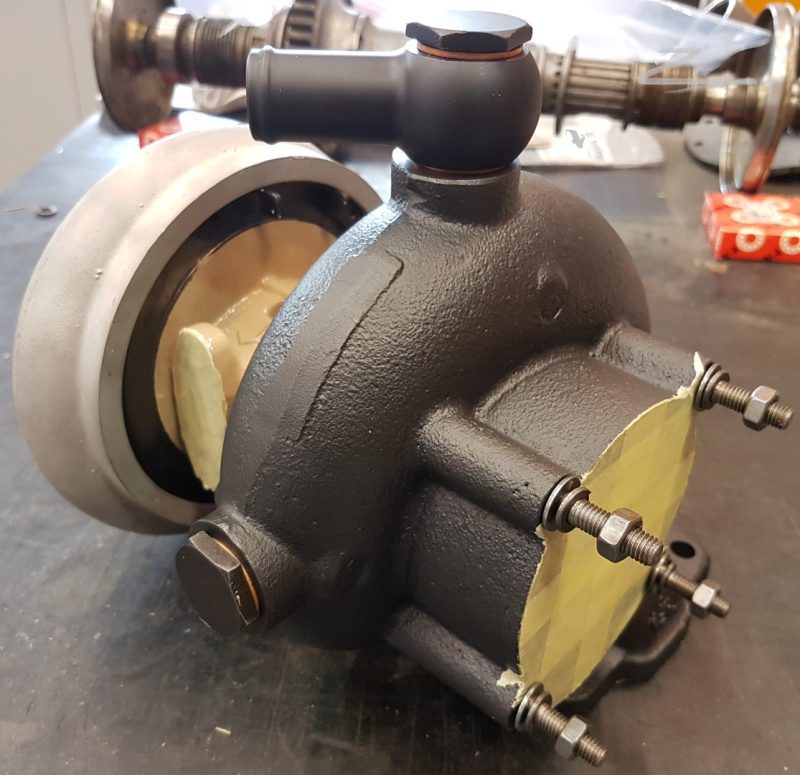

They had their two Holset turbochargers overhauled by a renowned company, but after the overhaul, they were not getting the boost.

Not good news, but it could have been far worse.

Once in the workshop, while carrying out the initial inspection and dismantle, our engineer came across the incorrect fitting of one of the most important components: the thrust washer.

Easily done? Yes. Should it happen? No

The client was lucky they hadn’t run the turbocharger for long because it could have easily seized resulting in much more major damage.

Unfortunately, this was not the only issue we found, as the heatshield had been fitted incorrectly and the exhaust housing cracked, all of which contributed to the lack of boost.

It got me thinking, that as an operator when you put your trust in a “reputable” company, how do you know everything has been done right?