With the slump in oil prices, there is additional pressure being applied across the engineering world affecting all of us and creating high levels of uncertainty for the future. Significant cuts are being made across the UK Oil and Gas sector, with particular scrutiny on operational costs and budgets being squeezed.

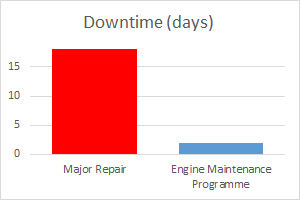

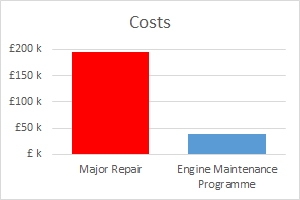

Pressures on budgets are leading to capex projects being postponed, or even scrapped. The knock-on effect is that it is even more critical that you are able to rely 100% on your current equipment to maximise productivity and output, and reduce the risk of increasingly costly downtime. Loss of production is even more damaging now that profit margins have dropped.

What can you do to increase the reliability of your current equipment and reduce the risk of downtime?

At Bartech we love the challenge of finding our clients innovative solutions to problems like this. There are a number of maintenance solutions, tailored to your needs, which we recommend to ensure that unexpected downtime, loss of production, or – even worse – down manning is reduced.

Our first 5 recommended ways are:

- Review of maintenance schedules and weekly/fortnightly checks

- We’ve seen engine failures because OEM maintenance schedules have not been carried out

- Even with low running hours, seals, joints and gaskets will perish and need replacing

- Do the operators carrying out the checks know specifically what to look for?

- 6 Monthly health checks

- One key area to check is potential cooling system blockages on watercooled engines

- Are there leaks that need rectifying before they turn into a bigger problem?

- Could there be warning signs of a failure round the corner?

- Engine upgrades and improvements to equipment over 30 years old

- Situated offshore, we have seen many engines with start problems caused by insufficient pre-heating

- Are the engines still reliant on 1970 technology?

- Does your engines have all the latest OEM upgrades?

- Better visibility of key engine data

- We have seen an engine failure which would have been prevented if exhaust temperatures were monitored and reviewed

- What engine data is routinely recorded?

- Is the key engine data (temperatures, pressures, etc) visible and analysed?

- Critical spares packages

- Are critical spares readily available if needed?

- Are you using the latest design parts with correct numbers?

- Does your engine have unique parts which need to be manufactured?

Whichever is the most appropriate for your business, we can help you to get the right solution to ensure that no matter how squeezed your budget is, you can rely on your safety-critical diesel engines to keep going.

To discuss your needs and get immediate advice on how to minimise the risk of costly and potentially dangerous downtime, contact our Key Account Manager, Robert Lee (rlee@bartechmarine.com) or call us on 01206 791552 today.

[bartech_cta]