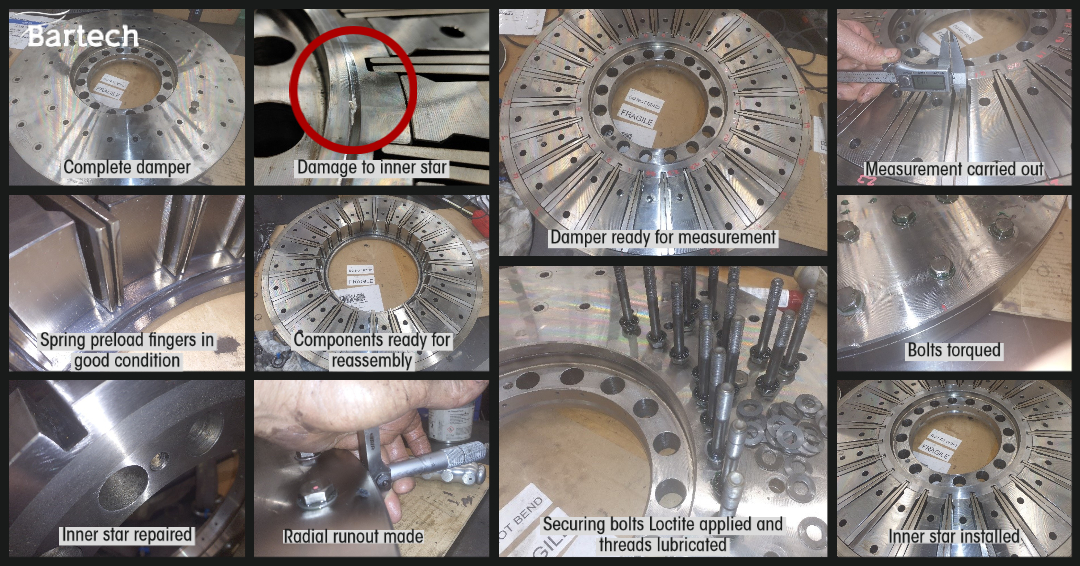

We were sent two Geislinger D6353 Dampers to overhaul – nothing out of the ordinary there, and the first one was completed without anything remarkable to report.

On the second damper, however, here is the work carried out and what we found:

- The Damper was first visually inspected on the exterior, checking for any major damage. None was found, so the ring of securing bolts was removed. This allowed the side plate to be lifted away, exposing the internal components of the damper.

- The side plate was checked for wear and damage, only slight indentations were noted and were within OE specifications.

- The spring packs were then individually marked and checked for wear, these were within limits and listed on the measurement sheet.

- The inner star was checked, along with the flange plate. The inner star had fretting around the O-ring groove. This was measured and was out of tolerance.*

*Now, this is where it could have gotten expensive. Without full knowledge of dampers and the possible repairs that can be made – another service company could have called for a new damper – at a considerable cost.

However, we knew this could be repaired and the inner star was sent away for 3rd party metal spraying and machining back to tolerance.

- All the components were then cleaned and reassembled. The oil sprayers were also checked, and it was ensured they were clear.

- Once the repaired inner star was checked following its repair, it was re-installed into the springs.

- The top plate was laid on top with new o rings.

- The radial runout of the damper was made.

- The securing bolts were sealed and torqued.

- The damper was then coated in anti-corrosion fluid and packaged ready for collection.