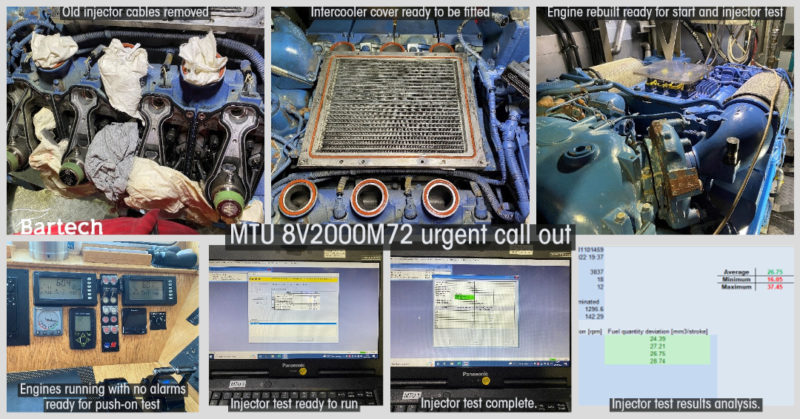

With the reliance on sensors, engine control systems and electronics, it is not unusual to be called out for engine fault codes, and that was the case last week when we attended a vessel out of hours in Ramsgate.

Their MTU 8V2000M72 engine was showing intermittent fault codes for injector lead issues which needed checking out.

Fortunately, the operator was already ahead of the game and had new leads onboard, so our first task was to get them installed and perform an injector test.

Once on the vessel, our engineer found the on-site engineers had already taken the initiative and stripped the engine to expose the leads, and he then continued the work alongside the vessel’s engineers.

The work scope consisted of:

- Removing the return fuel lines

- Removing the injector leads through the hole in the intermediate cover

- Installing and connecting the new leads to the injectors

- Re-fitting the return lines, then rocker covers

- The O-rings were greased and the intercooler cover fitted

- Fitting the inlet manifold elbows and ECU and breather pipework

This completed the rebuild, and the next step was testing.

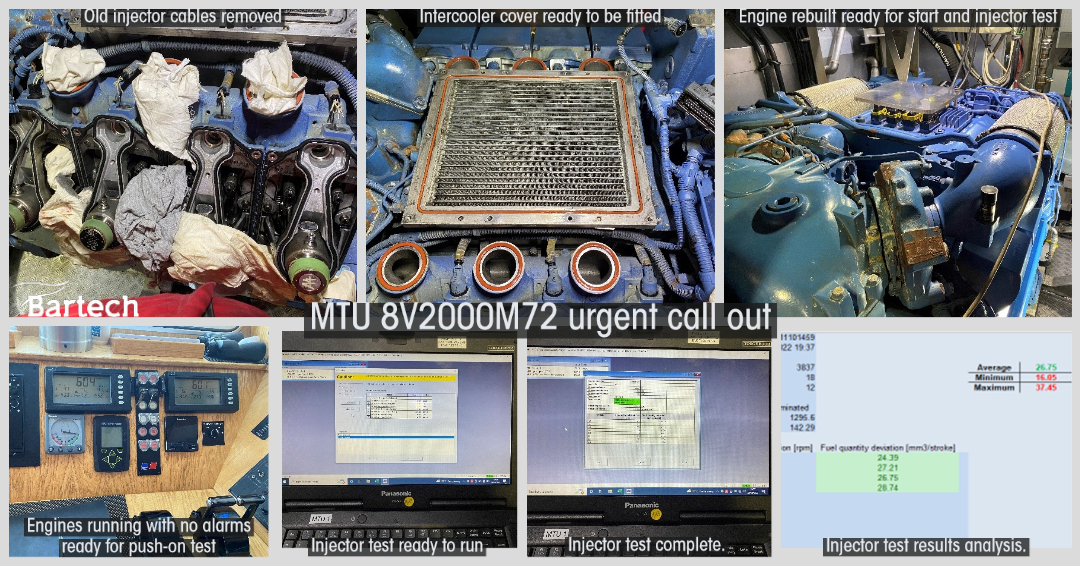

The engine was made ready to run, and with the ignition on, the diagnostic software was connected to the ECU to perform the injector test.

Because the engine was already partially stripped when we arrived on-site, this was the first time we were able to check the error logs which showed that cylinder A4 was the cause of the alarm.

The engine was then started and idled to warm up before carrying out a successful push-on test which showed no alarms at any stage:

- Initial run or while moving to complete the push-on test

- When pushed up against the dock and held at 1300 rpm to complete the test

- The injectors have since been analysed and all are within limits

A great example of the benefits of a strong partnership between operators and service providers to achieve successful outcomes like this.

An effective parts strategy, engineers working together and out-of-hours support meant no costly downtime for a vessel under contract.