You may remember my email about the RCA we carried out on a Deutz DFP6 fire pump engine?

If so, you’ll know that the engine had suffered extensive vibration damage.

To replace the failed engine, we used a donor that was overhauled and converted to match the same specification as the original.

And all this seemed to be working until we had the engine on test!

The test procedure consisted of checking for leaks, then running on idle before gradually adding load and increasing the speed all whist checking key engine parameters.

Everything was fine for the first 8 hours of running, then things went awry.

At 75% load, with 18 PSI of boost and 230 HP, the boost hose popped from the turbocharger.

Bad news.

We carried out the repairs and restarted the engine at idle, and as we were running through preliminary checks we saw water coming out of the intake manifold, so shut down the engine again.

When we investigated this further, we found the source of the leak was the charge air cooler. One of the signs was that it was cool to touch when it would normally be around 110°C.

The air cooler was removed for further inspection, and with the paint removed, we could see that the unit was of all copper construction, handmade and soldered together, showing the core and housing are a complete unit.

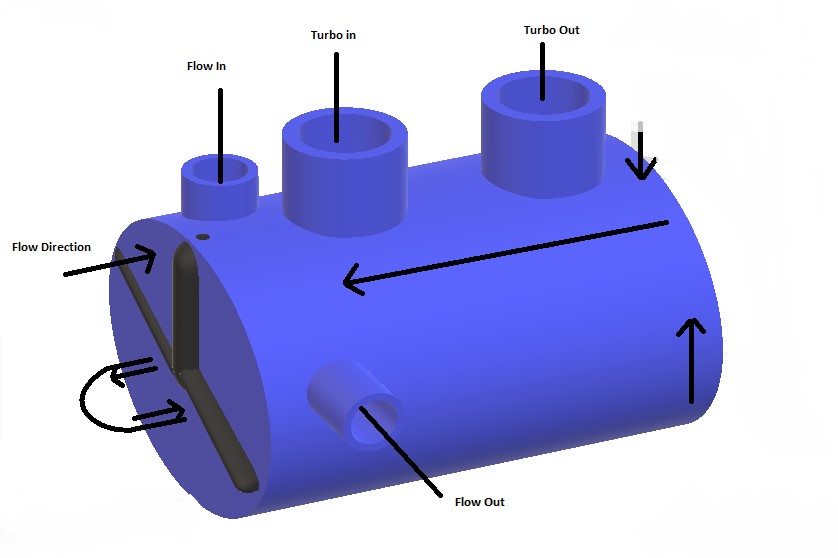

The fresh cooling water enters and exits the cooler at the same end of the cooler after the water passes through the cooler a total of 4 times before exiting to lower the charge air temperatures from 110°C to 50°C.

There is no bracing of the tubes centrally in the cooler making them susceptible to fracture through excessive movement.

This cooler was from the original engine, and although it was tested and found to hold pressure before being used on the replacement engine, there was an inherent weakness that caused the failure.

On discovering this failure, it came to light that the previous cooler had a similar issue and was replaced with the same type within the last 5 years. With the information of historical failures and considering the design and the vibrations experienced by the cooler, the current air cooler design is not suitable for this application.

The cooler is now being upgraded to a conventional serviceable type cooler that has a well-braced core like this:

With the previous vibration issues, we are also strengthening the mounting plate and installing some isolating mounts to limit vibration levels through the core.

The takeaway here is simple:

It’s vital to share as much historical information as possible with any service provider you use so they can put a suitable solution to prevent additional failures, and if you have regular cooler failures, it may be time to upgrade.

Missed the original RCA article? It’s here.