Knowledge Base

Posts in the category of: Knowledge Base

-

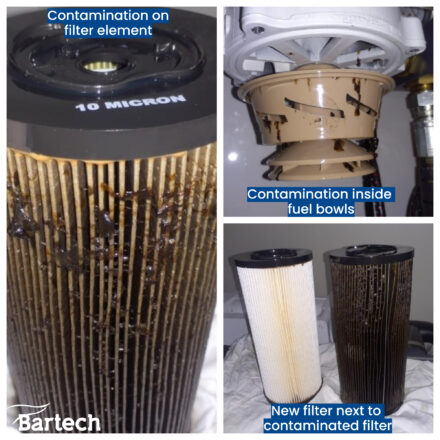

Check Your Filters: Important Maintenance Notice

March 14, 2024

Engine Maintenance

We wanted to share some recent findings from our service work on two Caterpillar C18 ACERT main engines and gearboxes.…

Read more -

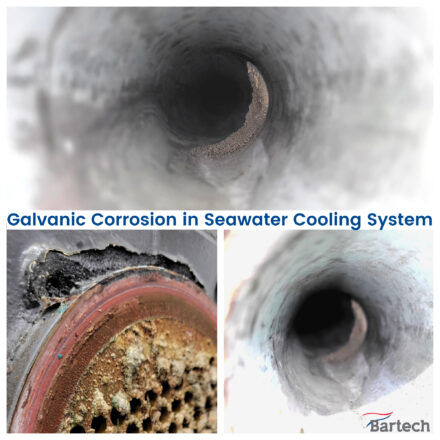

Critical engine maintenance

February 15, 2024

Engine Maintenance

Here's an issue we found whilst working on an engine’s seawater cooling system recently that can easily happen if you…

Read more -

Intercooler performance

February 15, 2024

Engine Maintenance

Bent over fins on your intercooler? Bent fins act as a bottleneck, restricting airflow through the intercooler. This obstruction can…

Read more -

5 Year Downtime

January 17, 2024

Knowledge Base

We wanted to share something that highlights the intricate challenges often faced by vessel owners. We were recently approached by…

Read more -

Minimise disruption, maximise performance

December 13, 2023

Engine Maintenance

As you know, we share a lot of case studies relating to the work we do, helping our clients with…

Read more -

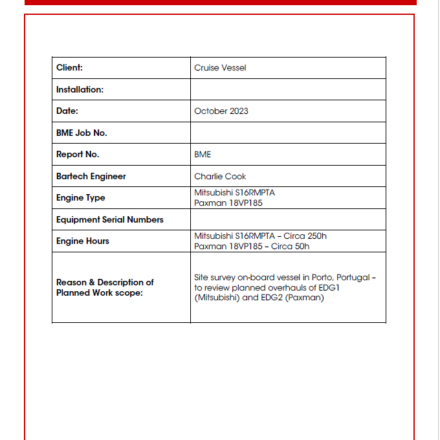

Site survey in Portugal

December 6, 2023

Highlighted

Hopefully, you will know by now that at Bartech, we are committed to providing the highest level of service. Recently,…

Read more -

Painful experience?

November 8, 2023

Highlighted

In a change from our usual posts, we wanted to take a moment to share our recent experience with one…

Read more -

Something new from Bartech

October 12, 2023

Highlighted

At Bartech, we’re always looking out for ways we can serve our customers even better. And earlier this year, an…

Read more -

WHAT’S THE POINT OF NET ZERO? (PART ONE)

October 6, 2023

Knowledge Base

For further information, please contact Dr Erik Jacobi here: ejacobi@essex.ac.uk If you would like to attend, RSVP here: jonathan.sparkes@buyerdock.com

Read more -

Diesel Engineers’ Resource Volume 2

August 23, 2023

Knowledge Base

The first edition of our Diesel Engineers’ Resource was extremely popular, so popular that we were out of hard copies…

Read more

Proud to be supporting:

Engineer Resource Vol. 2 is now out for FREE download. Get your copy now!

A collection of articles to help you improve engine reliability, performance and safety specifically for engineers, brought to you by Bartech Marine. Simply enter your email below to get instant access.

By completing this form you are agreeing to our privacy policy.