Improving the safety, reliability and performance of your critical diesel engines

Partner with someone that can provide the expertise, knowledge, and parts you need; when you need them.

Get support nowSometimes diesel engines don't work as hard as they could for you...

Do you recognise any one of these common problems?

-

Waiting too long for availability of engineers

-

Paying too much or waiting too long for spares

-

Ongoing issues or recurring problems

Refreshingly customer-centric diesel engine specialists who know how to make your machines work harder for you.

We’re a family-owned business, yet some of the biggest and best names in the industry and across the world have made us their ‘go to’ solution when things don’t go quite to plan and when they’re experiencing downtime from broken parts or technical issues.

About us Get support nowProud to be supporting:

How can we help you?

Discover more about what we can do for your critical diesel engines by selecting an option below.

-

Services to help with your critical diesel engines

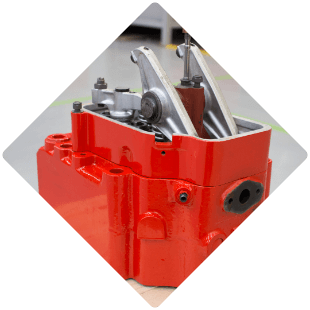

We provide operators with complete service and support for their diesel engines and associated equipment, specialising in diesel engines, engine governors, turbochargers and sheathed fuel pipes.

Find out more -

Sectors we specialise in

Since 1987, Bartech has been providing companies like yours with global safety through mechanical excellence across sectors reliant on critical diesel engines.

Find out more

“Thanks for the help, and the fact that you were able to keep your promises regarding delivery time etc.

We’ll keep in touch.”

URS

URS

“Many thanks for your help and cooperation, most refreshing to find a business that actually puts the customer first and understands the imperfect world that we operate in.”

Williams Associates

Williams Associates

“Thank you.

The site report and the overhaul at site have been conducted to a high standard.

Well done.”

Wood Group Asset Management Solutions

Wood Group Asset Management Solutions

We like to keep things simple....

Your time is precious so that's why we have just 3 easy steps for you to work with us.

-

1

Book a survey or review meeting

Fill in our short form and tell us what you require -

2

We get to work

We will sort all of your critical diesel engine needs -

3

Peace of mind

24-hour support backed by full documentation and a 12-month warranty

If you'd prefer you can simply call us anytime on

01206 673101 24hEngineer Resource Vol. 2 is now out for FREE download. Get your copy now!

A collection of articles to help you improve engine reliability, performance and safety specifically for engineers, brought to you by Bartech Marine. Simply enter your email below to get instant access.

By completing this form you are agreeing to our privacy policy.