Providing Safety Through Mechanical Excellence

Bartech has been building a strong reputation for improving diesel engine reliability, safety and performance since 1987.

Our aim is to be your most proactive, trusted engine maintenance partner.

Bartech has been building a strong reputation for improving diesel engine reliability, safety and performance since it was formed in 1987. Almost immediately we began supporting major companies such as Shell, Lockhead and the OEM, Paxman Diesels, who relied on our specialist knowledge.

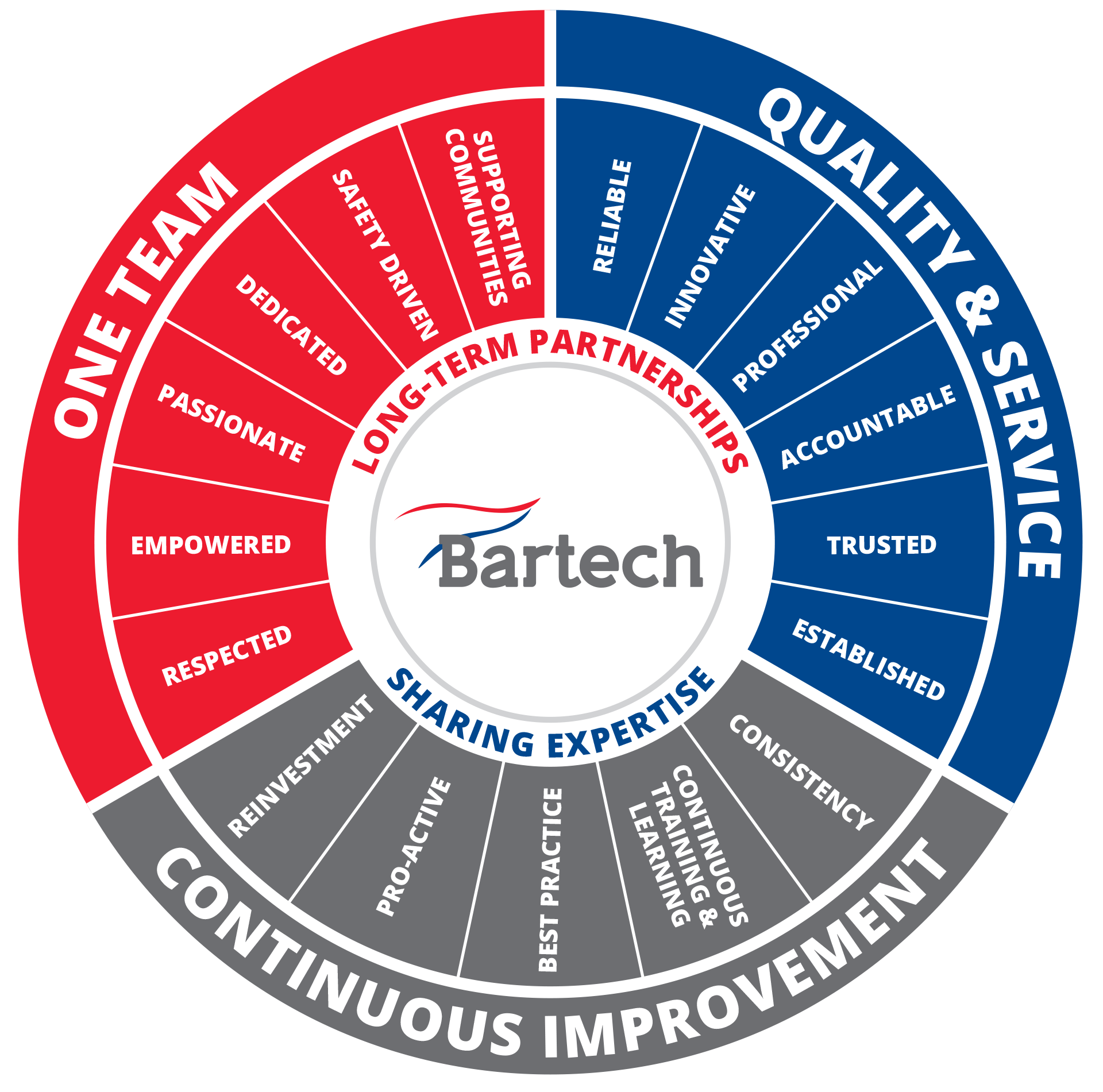

Fundamental to this growth has been the focus on our core beliefs of building long-term partnerships by sharing our expertise.

Even though our specialist diesel engineering services centre on engines, governors, turbochargers and fuel pipes, we constantly strive to enhance our support capabilities and develop our range of services.

Bartech has a strong team with varied specialised backgrounds including OEM training, CMM, machining, project management, quality, logistics, IT and administration which equips us to respond effectively and in a cost-efficient way to your specific requirements. These in-house skills are backed by the core company values reinforced by family ownership.

Our story – One man’s vision that spawned a family business

With a childhood fascination in engineering (particularly anything to do with Formula 1 cars) it was no surprise that our company chairman, Gerald Barnett (commonly known as Barney) began his engineering career at Paxman Diesels in Colchester back in 1966.

-

Gerald Barnett, Chairman (Left)

& Paul Bleck, MD (Right)Whilst at Paxman, Barney gained a thorough appreciation and understanding of the complexities of diesel engines as part of the development section supporting the RPH, YH and YJ models.

Following his time in development, Barney went on to travel the world as a service engineer, working on many different engine types and associated equipment.

By working on customers’ sites and vessels, Barney began to understand firsthand the pressures his clients were under, with every down day costing money in lost earnings, fines or additional running expenses.

-

Often, it wasn’t until he was on a vessel that the full extent of the problems he was tasked with fixing became evident, with misleading information provided beforehand and an increasing challenge unfolding.

Back in the ‘70s, communicating back to technical support was almost impossible, which often resulted in him needing to use his engineering knowledge to find root causes and safe solutions with the facilities and spares available to him at the time.

These experiences gave him a real understanding of the pain clients felt when their engines were out of action and how the same solution would not be right for every customer.

-

It was from these experiences that he identified a real need for an alternative option within the industry and established Bartech Marine Engineering in 1987 with his wife Jane.

Jane’s experience as a legal secretary was invaluable in establishing the administrative procedures and templates vital for any professional company and coupled with Barney’s expertise, the duo were the perfect team.

Fast forward to 2012 when Paul Bleck becomes Managing Director, and Bartech still holds true to those values – solution focused, responsive and technical excellence.

-

The Bartech Family

Bartech has grown substantially since forming in 1987, but remains a family-owned business, constantly looking to reinvest in facilities, equipment and training. It is through this investment we will continue to deliver the highest standards and innovations to benefit our clients.

Proud to be supporting:

What were you most impressed with working with Bartech?

“Attention to detail, competence of staff, knowledge, working to accurate quote, competitive pricing of all aspects from labour to parts.”

Jon Hawkins ~ Boluda Towage Europe

“Well done, it is great to see the final “three for three, FYFP 1, De-Sup Station and CW valve” risk mitigations now delivered safely before year end.

Can I reinforce and recognise the drive, team work and clear communications during the last month especially.

This rounds off a very positive risk mitigation year for Team Hartlepool and the wider support provided via CTO and the Supply Chain with 22 oo 23 Key Deliverables completed and handed back to the operations teams.”

Bill Liu ~ EDF

How did working with Bartech benefit you / your company on this project?

“When a fault was found with the water cooler adaptor plate, a new part was sourced and sent out to the platform the following day. This meant the crane could be returned to service as planned and therefore no downtime experienced.”

What were you most impressed with working with Bartech?

“The technical knowledge and speed of sourcing the required part. The platform also commented positively on the work ethic of the engineer on the job.”

Steven Bain ~ EnerMech

“Bartech provided us with a one-stop solution for our Waukesha units.

Our previous supplier had become unreliable so moving to Bartech was a game changer.

We are now confident that parts will arrive on time plus we have access to Bartech’s knowledge and advice…Their wealth of Waukesha experience has been extremely helpful when making decisions on parts. Communicating with Bartech is always a pleasure: they are friendly, approachable, knowledgeable, and always able to deliver on our requests.

Big thank you to: Jamie, Ricky, Robert and Gary.”

Marcus Winfield ~ Shell

How could we have improved your experience with Bartech?

“Nothing as the experience was excellent.”

Peter Reynolds ~ Generator Power Systems DDGC

“Please pass on my thanks to your team for the fantastic effort in getting this rearranged visit complete.

We had constraints on labour and lead time of equipment however all went seamlessly.

Please also pass this on to Matt and William and thank them for their workmanship whilst offshore, very much appreciated by all here at Fairfield.”

Martin Baxter ~ Fairfield Energy

Quality Guaranteed

At Bartech, all our work is performed to the highest standards and is backed up by our warranty. When work is completed, a full report is written and will be available either via email or through our customer portal. We work with some major companies and organisations around the world, meeting the high standards they demand. We are FPAL registered and ISO 9001 approved.

Guarantees

We offer 7 guarantees how we can help you reduce your mechanical failures and cut expensive downtime.

-

1

Peace of mind

All parts supplied and work completed is covered by our full 12-month warranty and supported with all relevant test certification, measurement sheets and reports. -

2

Skill

A team with over 300 years’ combined experience in engineering, including OEM apprenticeships and training. -

3

Experience

Proud to have supported MAN, Shell, Lockheed, British Energy and Tanzanian Railways. Our spares have been fitted on vessels for the American, Indonesian, Spanish and Indian Navies, as well as the Royal Fleet Auxiliary. -

4

Excellent facilities

Our purpose-built head office includes a fully equipped workshop, dedicated governor bay, test facilities and machine shop including state of the art CNC and CMM machines. -

5

Innovative

With a wide breadth of engineering experience and training, our engineering team are able to offer various solutions to give you the best option. -

6

Stock

We hold over 3,000 different items, all detailed on our bespoke computer system, helping us respond quicker to you. -

7

Customer Support

You can depend on us for complete service contracts or individual projects. Our engineers travel the world to support customers in Africa, the Middle East, Far East, Europe and the Americas. All projects are planned and monitored using Gantt charts and Action Trackers to ensure promises are met.

Engineer Resource Vol. 2 is now out for FREE download. Get your copy now!

A collection of articles to help you improve engine reliability, performance and safety specifically for engineers, brought to you by Bartech Marine. Simply enter your email below to get instant access.

By completing this form you are agreeing to our privacy policy.